- Home

- Apparel Services

- Cut and Sew Manufacturer

- Private Label Clothing Manufacturer

- DTF Printing

- Sublimation Printing

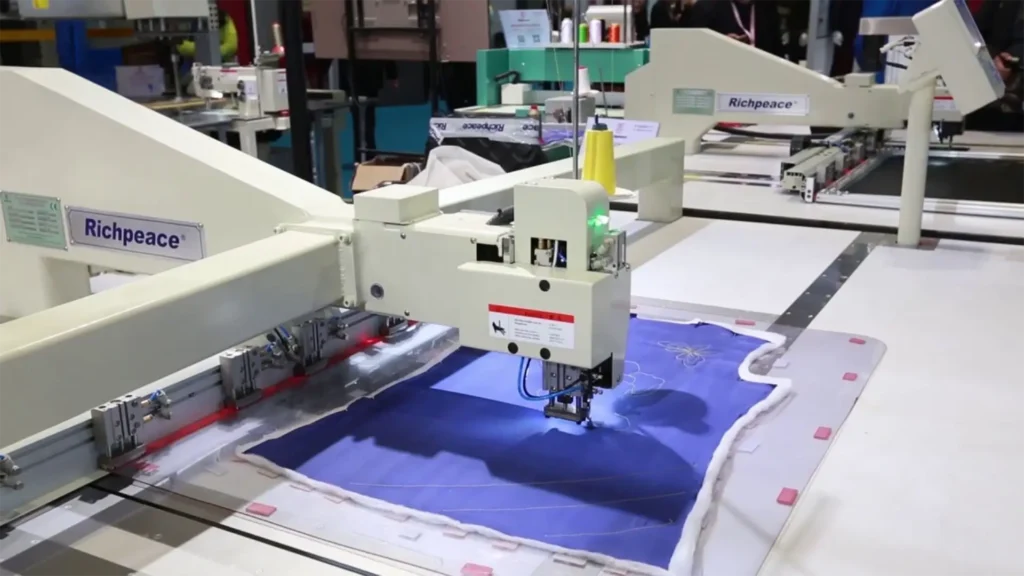

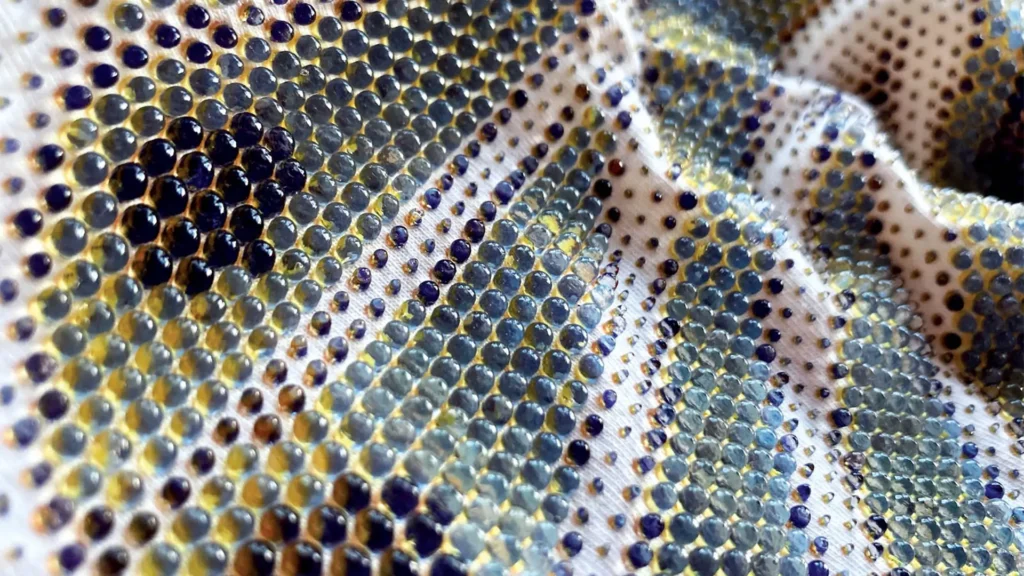

- Embroidery Manufacturer

- Custom Design Service

- AI Generated Design Service

- AI Photo Studio Service

- Products

- Shirts Manufacturer

- Sportswear Manufacturer

- Activewear Manufacturer

- Hoodies Manufacturer

- Tracksuits Manufacturer

- Shorts Manufacturer

- Accessories Manufacturer

- Business Uniform Manufacturer

- Streetwear Manufacturer

- About

- Success Stories

- Blogs

- Contact Us