Sewing and Assembly Equipment

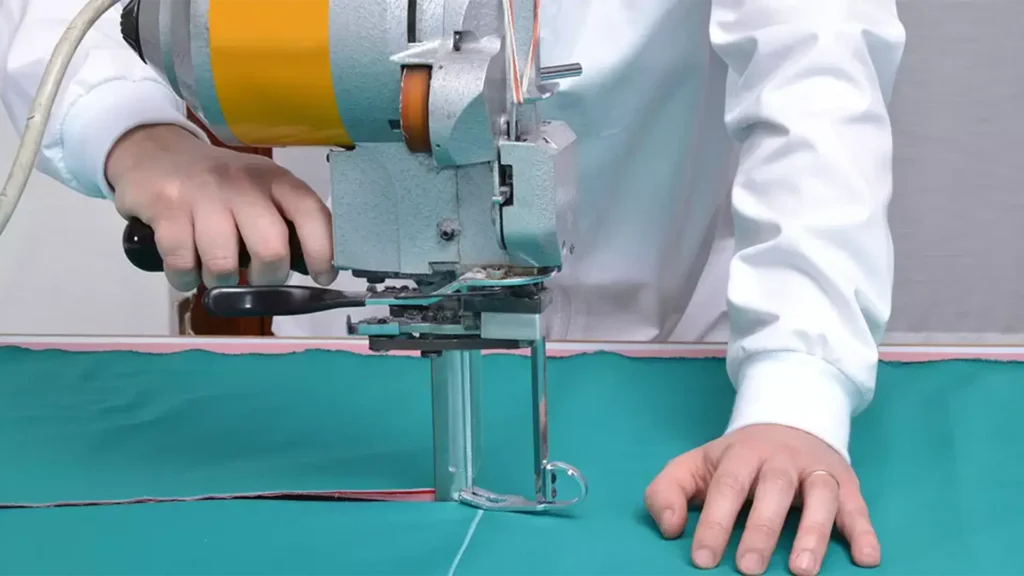

Sewing is one of the most recognizable stages of garment production. This is where individual fabric pieces come together to form a complete garment. Various assembly machines are used, each with a specific purpose.

Sewing Machines

Sewing machines are the most essential part of the apparel industry, with different types tailored for various stitching techniques:

These are the most common sewing machines, producing firm, straight, that securely hold fabric pieces together.

Also known as sergers, these machines finish the edges of the fabric to prevent fraying, creating a polished and durable seam.

Chain stitch machines offer flexibility and resilience for garments that require stretchable seams, like sportswear.

Button Hole and Attaching Machines

Specialized machines handle the intricate task of creating buttonholes and attaching buttons. These machines ensure precision and consistency, particularly in garments like shirts and blazers, where these details significantly impact the overall quality.

Embroidery Machines

Embroidery machines add aesthetic value to garments by stitching decorative designs. With modern computerized embroidery machines, manufacturers can produce intricate patterns with remarkable speed and accuracy, making them a popular choice for high-end and customized clothing.

Pressing and Finishing Equipment

After sewing, garments require finishing touches to look exceptional and professional. This phase involves several types of equipment designed to enhance the final product’s appearance.

Fusing Machines

Fusing machines bond interlining materials to fabrics using heat and pressure. This process adds structure and stability to garments, ensuring they maintain shape over time. For example, in dress shirts or jackets, fusing gives collars and cuffs their crispness.

Ironing and Pressing Machines

Ironing is an essential finishing process to remove wrinkles and create a smooth, appealing surface. Steam-based pressing machines are particularly effective for mass production, allowing operators to quickly handle large volumes without compromising quality.

Thread Trimming Machines

Even the finest garments can look unprofessional if loose threads are left hanging. Thread trimming machines swiftly and efficiently remove these unwanted threads, leaving the garment clean and ready for packaging.